Introduction

The Metal Fabrication Market refers to the industry involved in cutting, bending, assembling, and shaping metal materials into finished products or components. These fabricated metal parts play a critical role across construction, automotive, aerospace, energy, electronics, and heavy machinery sectors. From structural frameworks to precision-engineered components, metal fabrication supports both everyday infrastructure and advanced industrial applications.

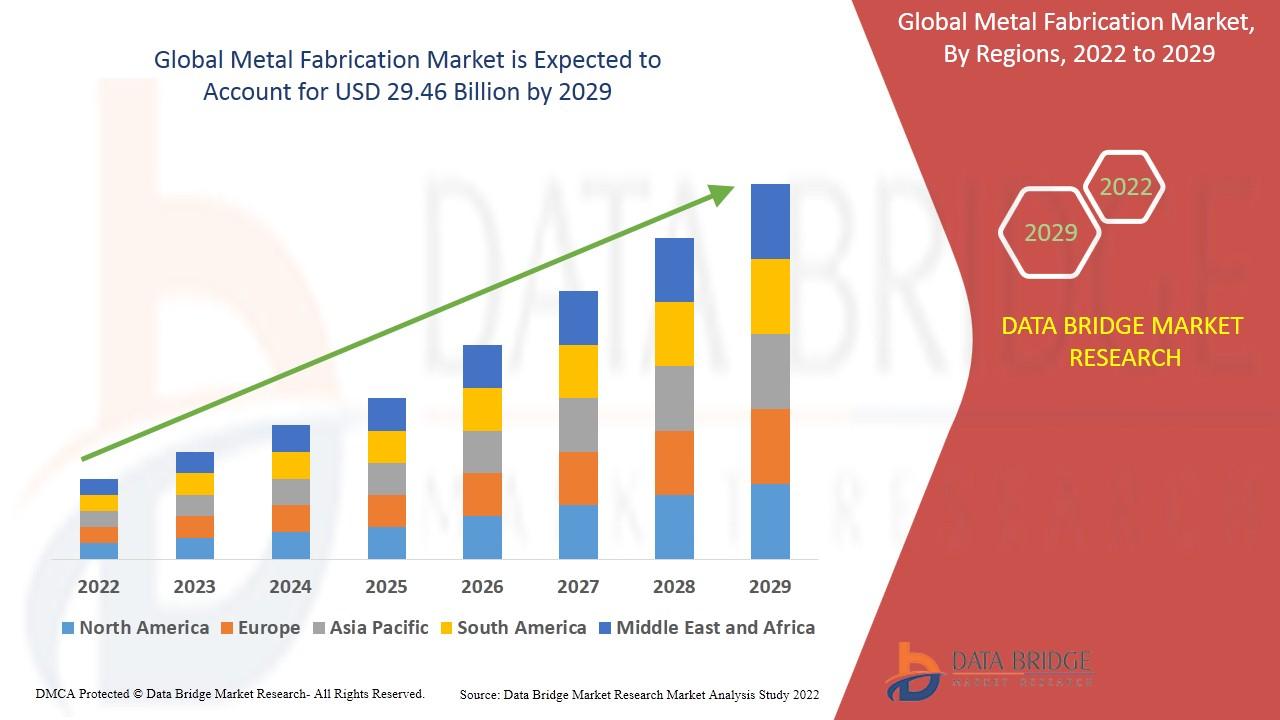

In recent years, the Metal Fabrication Market has shown steady growth due to rising industrialization, urban development, and manufacturing expansion. As economies invest in infrastructure and advanced manufacturing, demand for high-quality fabricated metal products continues to rise. The market contributes significantly to global economic activity by supporting supply chains, employment, and technological progress.

Stay ahead with crucial trends and expert analysis in the latest Metal Fabrication Market report. Download now: https://www.databridgemarketresearch.com/reports/global-metal-fabrication-market

Market Overview

The Metal Fabrication Market has grown consistently over the past decade. Increased construction activity, vehicle production, and industrial equipment manufacturing have fueled demand for fabricated metal products. Historically, the market expanded alongside industrial growth, particularly in developed economies with strong manufacturing bases.

Today, the market is evolving due to automation and advanced fabrication techniques. Technologies such as computer numerical control machining, laser cutting, and robotic welding improve precision and efficiency. These advancements support higher production volumes and better product quality.

Asia Pacific holds a large share of the Metal Fabrication Market due to rapid industrialization and infrastructure development. Countries in this region invest heavily in construction, transportation, and energy projects. North America and Europe also remain strong markets, supported by automotive manufacturing, aerospace activities, and technological innovation. Emerging economies contribute to future growth as manufacturing capacity expands globally.

Key Market Drivers

One major driver of the Metal Fabrication Market is the growth of the construction industry. Urbanization and infrastructure projects increase demand for fabricated metal structures, beams, and frames. Governments invest in transportation networks, smart cities, and public facilities, which directly support market expansion.

The automotive and transportation sector also drives growth. Vehicle manufacturers require fabricated metal components for chassis, body structures, and engine parts. As electric vehicle production increases, demand for lightweight and high-strength metal components grows further.

Technological advancement acts as another key driver. Automation and digital fabrication tools reduce production time and material waste. For example, laser cutting allows precise shaping of complex designs, improving efficiency and lowering costs.

Energy and industrial equipment sectors also contribute. Fabricated metal parts are essential for power plants, renewable energy systems, and heavy machinery. As global energy demand rises, investment in these areas supports steady market growth.

Market Segmentation

The Metal Fabrication Market can be segmented by type, application, end-user, and region. By type, the market includes cutting, welding, machining, stamping, and forming. Cutting and welding segments perform strongly due to their widespread use in construction and manufacturing.

By application, the market serves structural fabrication, industrial equipment, automotive components, and consumer goods. Structural fabrication holds a significant share because of ongoing infrastructure projects worldwide. Automotive applications also show strong performance due to continuous vehicle production.

End-user segmentation includes construction, automotive, aerospace, energy, electronics, and manufacturing. The construction sector leads the market, followed by automotive and industrial manufacturing. Aerospace fabrication grows steadily due to demand for precision and high-performance components.

Regionally, Asia Pacific dominates the market, while North America and Europe maintain stable growth. Developing regions show rising demand as industrial activities expand.

Competitive Landscape

The Metal Fabrication Market is competitive and fragmented, with numerous global and regional players. Leading companies focus on expanding production capacity, adopting advanced technologies, and improving service offerings. Innovation remains a key strategy to stay competitive.

Many companies invest in automation and robotics to enhance productivity and reduce labor costs. Others pursue mergers and acquisitions to expand geographic reach and strengthen capabilities. Partnerships with original equipment manufacturers and construction firms also help secure long-term contracts.

Competition encourages continuous improvement in quality, speed, and customization. As customers demand tailored solutions, fabrication companies focus on flexibility and precision. This competitive environment drives technological progress across the market.

Challenges and Restraints

Despite positive growth trends, the Metal Fabrication Market faces several challenges. Fluctuating raw material prices affect production costs and profit margins. Steel and aluminum price volatility creates uncertainty for manufacturers and customers.

High initial investment requirements also restrain market growth. Advanced fabrication equipment and automation systems require significant capital. Small and medium enterprises may struggle to adopt new technologies due to cost constraints.

Skilled labor shortages present another challenge. Modern fabrication processes require trained operators and engineers. Lack of skilled workers can limit productivity and slow adoption of advanced techniques.

Environmental regulations and sustainability concerns also impact the market. Manufacturers must comply with emission standards and waste management rules, which can increase operational complexity and costs.

Future Outlook

The future of the Metal Fabrication Market appears positive, supported by industrial growth and technological innovation. Demand for customized and high-precision components will continue to rise. Automation, digital manufacturing, and smart factories will shape the next phase of market development.

Emerging opportunities include lightweight metal fabrication for electric vehicles and renewable energy systems. Advanced materials and hybrid fabrication techniques will gain importance. Sustainability initiatives will encourage the use of recyclable metals and energy-efficient processes.

Growing investments in infrastructure across developing regions will further support market expansion. As industries modernize and diversify, the Metal Fabrication Market is expected to remain a critical pillar of global manufacturing.

Conclusion

The Metal Fabrication Market plays a vital role in supporting construction, manufacturing, and industrial development worldwide. Strong demand from key sectors, combined with technological progress, continues to drive growth. While challenges such as raw material volatility and skill shortages exist, innovation and investment help address these issues.

Looking ahead, the market holds strong potential. Advanced fabrication technologies, expanding industrial activities, and infrastructure development will shape a resilient and dynamic future for the Metal Fabrication Market.

Frequently Asked Questions (FAQs)

What is the growth rate of the Metal Fabrication Market?

The Metal Fabrication Market is growing steadily due to rising construction, manufacturing, and industrial activities worldwide.

Which region is expected to dominate the Metal Fabrication Market in the future?

Asia Pacific is expected to dominate due to rapid industrialization and large-scale infrastructure investments.

Who are the leading players in the Metal Fabrication Market?

The market includes global manufacturers and regional fabricators focusing on automation, innovation, and capacity expansion.

What are the major challenges faced by the Metal Fabrication Market?

Key challenges include raw material price fluctuations, high capital costs, skilled labor shortages, and regulatory compliance.

What are the future opportunities in the Metal Fabrication Market?

Future opportunities include advanced automation, electric vehicle components, renewable energy projects, and sustainable fabrication practices.

Browse More Reports:

Global Dental Splints Market

Global Disposable Incontinence Products Market

Global Fondaparinux Market

Global Hypercholesterolemia Drugs Market

Global Iris Retractor Market

Global Liquid Processing Equipment Market

Global Loop Diuretic Market

Global Nano Bioreactor Market

Global Oral Hypoglycemic Agents (OHAs) Market

Global Palatants Market

Global Peripheral Myelin Protein 22 (PMP22) Gene Related Disorder Market

Global Radiological Diagnostics Market

Global Thyroid Cancer Drug Market

Global Torque Limiter Market

Global Application Programming Interface (API) Testing Market

Global Catalepsy Treatment Market

Global Hybrid Fruits and Vegetable Seeds Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- [email protected]